——Electron Beam Cross-Linked|High-Clean, Long-Lifetime ESD Protection Exper

✍️ Original article by YUFA Polymer.

�� For inquiry, please contact: info@yufapolymer.com

�� Production Site: Shenzhen, China

Whether it's 5mm thin cushioning or support over 300mm thick, our anti-static IXPE foam is manufactured using advanced electron beam cross-linking technology, achieving the ideal balance between lasting electrostatic discharge (ESD) protection and precise cushioning. The product is cross-linked at the molecular level with no chemical residues, featuring stable and controllable surface resistance (10⁵–10⁹Ω), providing clean and reliable protection for high-value, highly sensitive applications.

Why Choose Anti-Static IXPE Foam?

✅ Clean and Lasting Anti-Static Performance

Surface and volume resistance are stably controlled (10⁵–10⁹Ω), ensuring durable anti-static effectiveness. The pure manufacturing process carries no risk of chemical additive migration, making it particularly suitable for precision electronics and cleanroom environments.

✅ Superior Performance from Electron Beam Cross-Linking

The uniform, fine closed-cell structure delivers exceptional resilience and compression fatigue resistance. It resists permanent deformation over long-term use, providing consistent cushioning protection.

✅ Lightweight, High-Cleanliness, Odorless

The material is lightweight. With no chemical cross-linking agents added during production, it is truly dust-free, low-VOC, and odorless, meeting high-standard requirements for medical, optical, or potential food-contact scenarios.

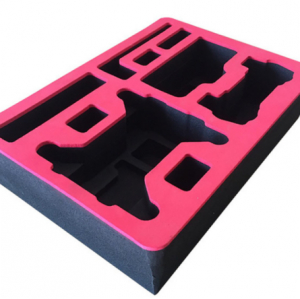

✅ Flexible Processing for Precision Customization

The stable foam structure allows for precision die-cutting, punching, adhesive backing, and laminating. It offers high dimensional accuracy and smooth edges, meeting demands for complex structural designs.

Complete Specifications to Match Your Needs

· Thickness Range: 5mm – 300mm (Custom thicker options available)

· Density Options: Low Density (Cushioning) / Medium Density (General Purpose) / High Density (Support)

· Standard Color: Black (Standard ESD identification color)

· Available Forms: Sheets, Rolls, Precision Die-Cut Parts

Designed for High-Standard Industries

�� Semiconductors & Chips: Wafer carriers, IC trays, chip packaging liners

�� High-End Electronics: PCB, sensor, communication module handling and storage

�� Medical & Optics: Medical device packaging, optical lens protection, display module shielding

�� Automotive Electronics: Anti-vibration and ESD packaging for ADAS components, vehicle control units

�� Precision Instruments: Transportation and storage protection for scientific research equipment and laboratory instruments

The Core Advantage of IXPE: Sourced from Radiation Cross-Linking

Our IXPE foam utilizes electron beam irradiation technology, creating a three-dimensional polymer network through a pure physical process. This means:

· Purer: No chemical residues, extremely low odor.

· More Stable: Uniform, fine cells ensure longer-lasting physical properties.

· More Reliable: Guarantees product consistency from the source, suitable for the most demanding environments.

�� Contact Us

YUFA Polymer Products Co., Ltd.

�� Address: Shenzhen, China

�� Email: info@yufapolymer.com

�� Web: www.yufapolymer.com